Baltimore Aircoil Company manufactures a wide array of efficient evaporative condensers to meet the needs of any industry. For more than 70 years Baltimore Aircoil Company has been evolving the development of cost effective heat transfer solutions. Their products are engineered to be low maintenance units with minimal life cycle costs. It is for these reasons that Baltimore Aircoil Company products are so popular across many industries.

When you want the best evaporative condensers, cooling towers, or closed circuit cooling towers around, look no further than ARESCO, Inc and the Baltimore Aircoil Company for your cooling needs. We can even help reduce your electrical costs and run your engine room cooler with our patented Desuperheater Design that reduces the discharge superheat from the booster compressors to the high stage compressors.

Evaporative Condensers

Designed for Industrial refrigeration, industrial processes, and HVAC, BAC’s evaporative condensers lower system condensing temperatures thereby reducing compressor horsepower, saving up to 15% energy compared to traditional air-cooled systems. This cost-effective cooling solution condenses refrigerant vapor in a coil that is continually sprayed with water. As the water evaporates, fans reject this heated vapor to the atmosphere.

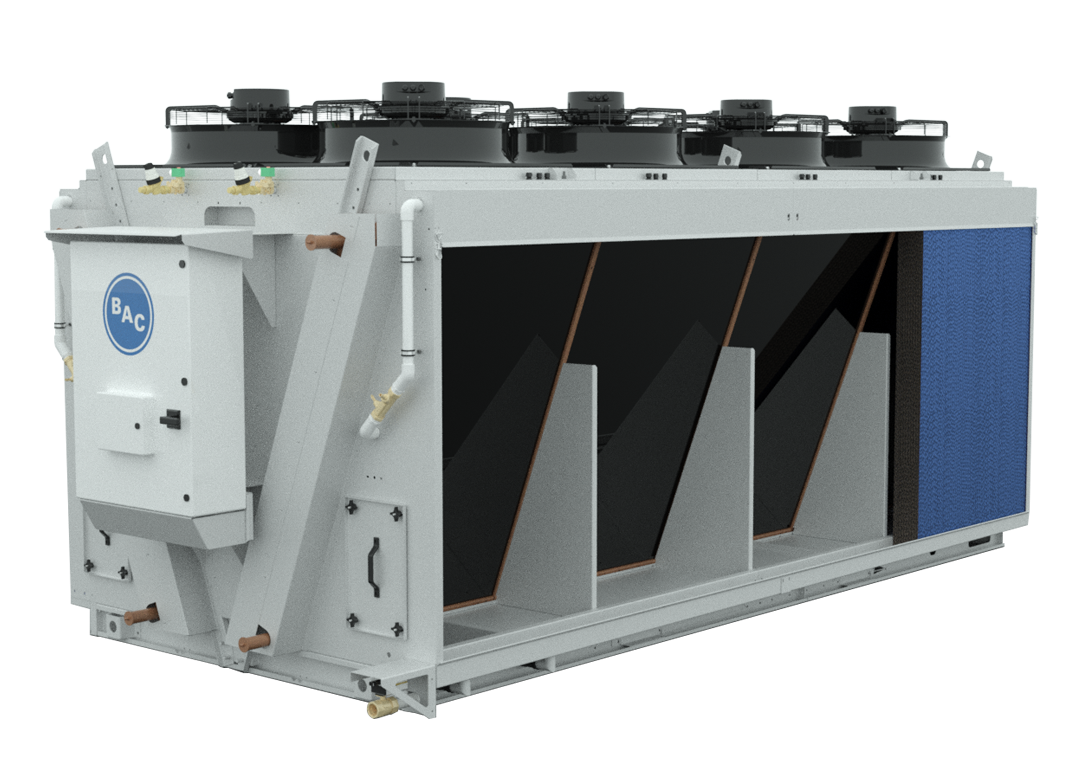

TrilliumSeries™ Adiabatic Products OPTIMIZE ENERGY AND WATER SAVINGS FOR REFRIGERATION

TrilliumSeries™ Adiabatic Products combine the best of evaporative and dry cooling to optimize energy and water savings. Users can reduce peak energy use by 44% vs. traditional air-cooled products or reduce water use by 90% vs. traditional evaporative products. For all of your commercial and industrial refrigeration application needs CO2, ammonia, and fluid cooler models are available.

- Up to 376 tons2

- Adiabatic // EC Fans // EcoFlex Controls

Lowest System Energy UP TO 44% PEAK ENERGY REDUCTION*

- Achieve lowest condensing temperatures and compressor energy savings year-round with BAC’s highest-efficiency and fully-wetted pre-cooler pads and daily self-clean protocols

- All models reduce system refrigerant charge vs. traditional air-cooled equipment but to further reduce charge, a TrilliumSeries™ Fluid Cooler can be combined with a fluid loop to reject heat

- Optimize unit and compressor energy with built-in capabilities for head-pressure and TD control, via remote fan control or self-contained operation with the plug-and-play Ecoflex Controls

- Different modes available to achieve peak performance during the day and conserve energy and limit sound at night

- Potential for substantial state and local energy rebates

* Compared to a system using air-cooled units by operating compressors at significantly lower condensing temperatures.

Permission received to have pictures and descriptions described here.

Home » Baltimore Air Coil (BAC)